About Us

13 Long Years Of Manufacturing Excellence With Quality At It's Best!

The SDET Brewing Solutions brand of brewery equipment continues to be the sought-after standard with craft breweries for over 10 years. With corporate headquarters located in Jinan City, China, sales and support offices in China, Canada, The United States, Britain, France, and Australia, along with manufacturing facilities in Jinan and Qingdao China.

SDET’s team has been leaders in the craft beer industry globally providing quality commercial brewing equipment for more than 1,000 projects.

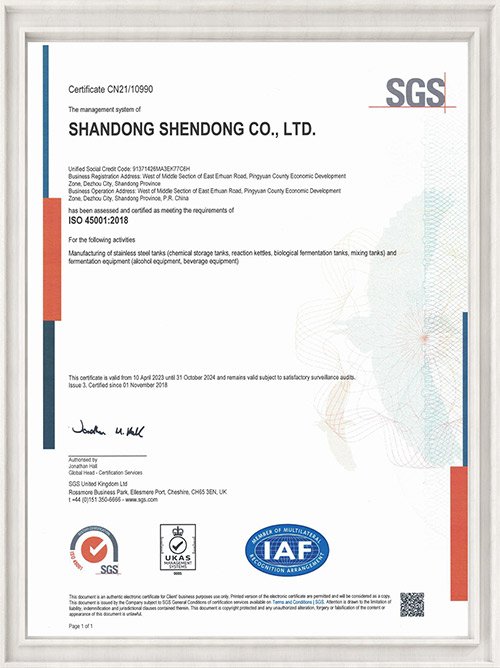

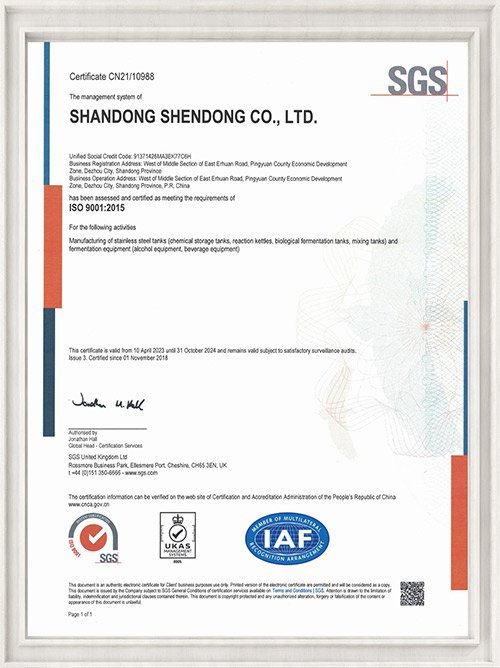

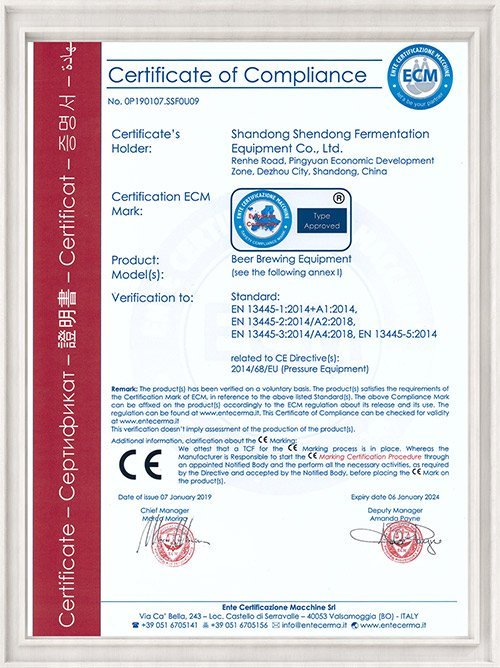

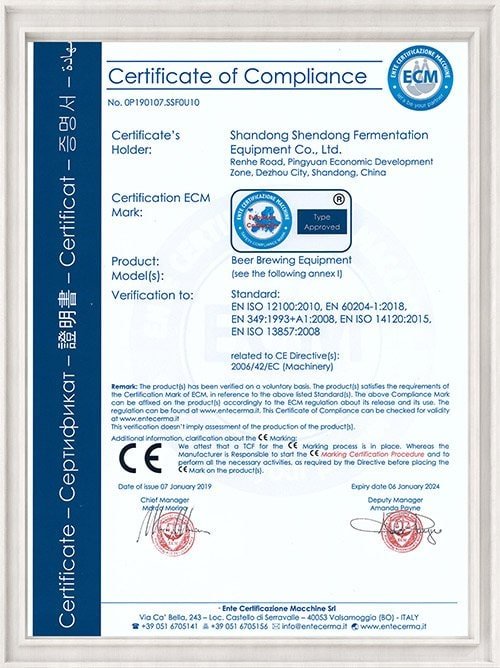

INTERNATIONAL CERTIFICATIONS

SDET is a national high-tech enterprise with 15 patented technologies in China, and also achieved ISO series certification ISO9001:2015; ISO14001:2015; ISO 45001:2018; CE ; ASME Certification.

ISO 9001

Certification for the Quality Management System

ISO 14001

Certification for the Environmental Management System

ISO 45001

Certification for the Quality Management System

CE

Certification of Compliance

ASME

American Society of Mechanical Engineers

MAIN PROCESSING EQUIPMENT

Laser Plate Cutting

Cutting accuracy ±0.05mm, cutting surface is smooth and free of oxidation.

High cutting efficiency, cutting process is all numerically controlled.

Works for SUS plates with thickness ≤12mm to meet a variety of different needs.

Laser Tube Cutting

High cutting accuracy with small deformation, cutting surface smooth and free of oxidation, which is beneficial for later welding

High production efficiency.

Laser Welding

Process range is 2 meters * 15 meters.

It is used for welding the cooling corrugated plate, especially for large fermenters of 50, 100, 200, and 300 tons. High welding quality with long service life.

Laser Dishhead Cutting

High cutting precision, high production efficiency, smooth cutting edge without burrs, which is convenient for subsequent welding.

Automatic Welding

High welding strength, Good welding quality, fast welding speed. The surface of the weld area is beautiful with small heat affected zone and deformation, and it is welded on one side and formed on both sides.

Automatic Bending

Controlled by the computer program and can achieve high-precision pipe bending. The bending angle and bending radius are very precise, which can effectively avoid pipe bending that does not meet requirements due to errors.

Automatic Roller

Four-axis CNC, the shell rolling plate is formed in one step, with high accuracy and fast speed. There is no straight edge, all arc transition at the edge joint of the stainless steel plate.

Automatic Polishing

Nylon belts as polishing consumables without carbon pollution, good mechanical polishing texture consistency, polishing accuracy up to 0.4um, computer-controlled operation with high stability.

Bruker Spectrometer

Imported from Germany, it is used to detect the metal element content of stainless steel plates to ensure that the raw materials used for production meet standards.

Roughness Measuring Instrument

The Mahr roughness tester imported from Germany can effectively detect the polishing accuracy of the Tanks inner surface, especially to meet the internal polishing requirements of fermentation tanks, it can print test reports directly.

Ultrasonic Thickness Gauge

Imported from the United States, quickly inspect the true thickness of the center of the stainless steel plate to meet the national standard for plate thickness requirements.

Tube Endoscope

It can effectively detect the welding quality of the inner surface of the pipeline and eliminate the occurrence of substandard pipeline welding, thereby eliminating sanitary dead corners inside the pipeline.